Electronics Manufacturing

Service

SESUNG’s specialty to achieve Premium EMS is demonstrated

by our perfect manufacturing line.

Through our All In One manufacturing services, we streamline the entire process

and enable customers to focus on matters most to their business.

Flexible manufacturing system can respond to needs of the high quality products

for our customers.

01

Features of SESUNG Manufacturing

- 1High-mix, Low-volume and Low-mix, High volume

- 2Short lead time and Quick response system

- 3Entire manufacturing process from SMT to assembly

- 4Major facilities : SMT Line, Auto Selective Soldering Line, Wave Soldering

Line, Conformal Coating Line, Chamber, ICT, X-Ray, Cleaning machine, JIG

02

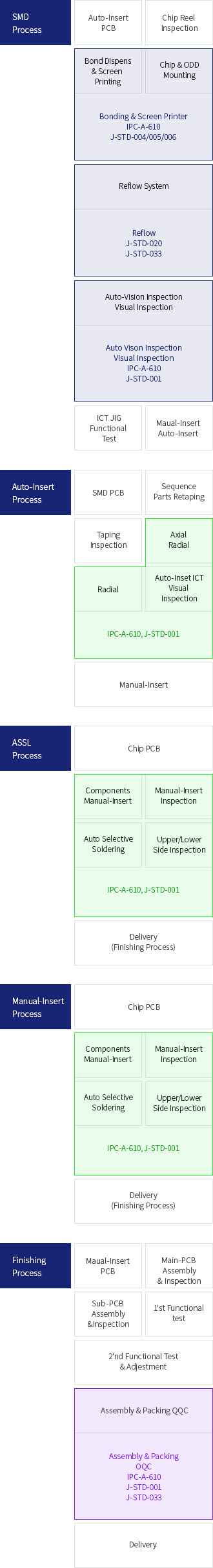

Manufacturing Process Map

We apply the latest manufacturing process standard combined with our advanced facilities to bring your

products to market better, faster and smarter.

Standards

for Product

Process

Step 1

Searching

& Purchasing

Step 2

IQC

(Incoming Quality

Control)

Incoming Quality Control

IPC - A - 600

/ J - STD - 020

J - STD - 033

/ J - STD - 075

- Chamber

- Coating Strength

Measuring Instrument

- Coating Thickness

Measuring Instrument

Step 3

PBA Process

(Printed Board Assembly)

SMT Process : IPC-A-610 / J-STD-001

Automatic Insertion : IPC-A-610 / J-STD-001

Manual Insertion : IPC-A-610 / J-STD-001

ASSL : IPC-A-610 / J-STD-001

Conformal Coating : IPC-SM-817 / IPC-A-610 / J-STD-001

Cleaning : J-STD-001 / IPC-TM-650

- PrinterAuto

Selective Spray

- Screen

Printer

- Wave

Soldering M/C

- Vision

- Auto

elective Solder

- Chip

Mounter

- Auto Selective

Soldering Machine

Inline

- Solder Temperature

Measuring

Instrument

- PCB Water

Cleaning Machine

- Conformal

Coating Machine

- Reflow

- N2

Generator

Step 4

IN-Circuit PCB Test

Functional Test

- X-ray

Machine

- In-Circuit

PCB Tester

Step 5

Assembly

Process

Step 6

OQC (Outgoing Quality Control)

EOL (End Of Line) Test

Lab View Test

QQC

IPC - A - 610

J - STD - 001

- Automatic

Function Tester

Step 7

Packing

Packing

J - STD - 033

Step 8

OBA

( Buyer Inspection)

QQC

IPC - A - 610

J - STD - 001

03

Manufacturing Service Map

Our manufacturing service map improves operational excellence, quality, productivity, responsiveness for customers.